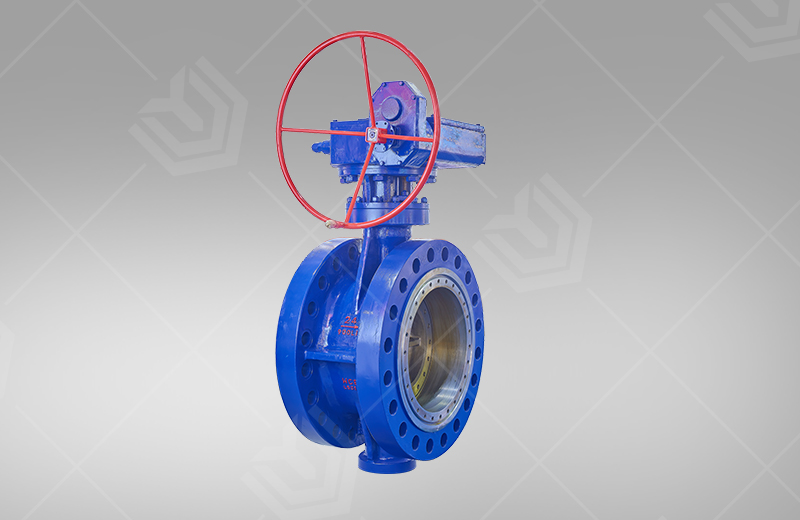

Intelligent explosion-proof electric ball valve

Technical Parameter

Item model number: Q941F

Nominal diameter: DN15-300mm

Nominal pressure: PN1.6, 2.5, 4.0, 6.4 MPa; ANSI 150, 300LB

Connection method: flange type

Optional actuator: explosion-proof adjustment type, intelligent explosion-proof adjustment type

Power supply voltage: AC220V, AC380V, DC24V (other special)

Applicable temperature: PTFE≤150℃, RTFE≤180℃, PPL≤300℃, hard seal≤450℃

Ambient temperature: Standard type: -20 - 80℃

Protection class: IP55, IP65, IP67

Product Description

The intelligent explosion-proof electric ball valve is composed of an angular-stroke explosion-proof electric actuator and a ball valve ball. It is composed of an electronic angular-stroke electric actuator 3810 or HQ series and a ball valve adjustment mechanism. The valve has the characteristics of simple structure, rapid switching, large flow capacity, zero leakage, etc. It is suitable for occasions with high viscosity, fluids containing fibers and solid particles. Explosion-proof electric ball valves are widely used in petrochemical, metallurgy, light industry and other industrial automation fields. Cut off or circulate the medium in gas and liquid pipelines. The actuator adopts an integrated design, the switch can be adjusted directly by inputting 220V power supply, and a servo module can also be built in, and the operation can be controlled by inputting a control signal (4~20mA DC or 1~5VDC) and a single-phase power supply. It is usually used in occasions with strict sealing requirements. In addition to controlling gas, liquid and steam media, it is also suitable for controlling sewage and media containing fibrous impurities. Widely used in petroleum, chemical industry, metallurgy, light industry, papermaking, power station, refrigeration and other fields.

Product Features

1. It is suitable for the occasions where two positions are cut off and adjusted.

2. It can realize the cutting and circulation of the medium in the transportation pipelines such as petroleum, chemical industry, papermaking, metallurgy, sewage treatment, and oil tanker.

3. Excellent sealing performance, large flow capacity, convenient loading and unloading maintenance, small flow resistance, reliable sealing, and even cut off.

4. Small size, light weight, large thrust, strong function, built-in servo amplifier, convenient operation and high reliability.

5. The flow direction can be arbitrary, and the adjustable range is wide. It can be used in high pressure and large-caliber occasions to control high-viscosity media with fibers and fine particles.

6. The direct connection method is adopted, the electric actuator has a built-in servo system, and there is no need to add a servo amplifier. The input and output signals can be controlled by 4-20mA and 3800VAC power supply. It has the advantages of simple connection, compact structure, stable and reliable action, etc.

The main technical parameters

| DN(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

Kv | 21 | 38 | 72 | 112 | 170 | 273 | 384 | 512 | 940 | 1452 | 2222 | 3589 | 5128 | 7359 |

| PN(MPa) | PN1.6、2.5、4.0、6.4MPa | |||||||||||||

| Leakage | Soft seal: zero leakage; hard seal: ≤ 10-5 of rated flow | |||||||||||||

| Body form | Two-section valve body (floating ball) | Two-stage valve body (fixed ball) | ||||||||||||

| Spool form | "O" ball valve core | |||||||||||||

| Seal packing | PTFE, metal graphite spiral wound gasket | |||||||||||||

| Connection Type | Flanged, Welded, Threaded | |||||||||||||

| Flow characteristics | Approximate quick opening characteristics | |||||||||||||

| Adjustable range | DN15-65 | DN80-300 | ||||||||||||

| 250:1 | 350:1 | |||||||||||||

| Basic error | ±1% | |||||||||||||

| Dead zone | ≤1% | |||||||||||||

| Return difference | ≤1% | |||||||||||||

| Proper temperature | Sealing surface | |||||||||||||

| PTFE≤150℃、RTFE≤180℃、PPL≤300℃、Hard sealing≤450℃ | ||||||||||||||

| Configure the actuator | Can be equipped with HQ, 3810 and other series of angular stroke explosion-proof electric actuators | |||||||||||||

| Control method | Switch in-position light (switch two-position control), intelligent adjustment (4-20mA analog signal control) | |||||||||||||

Material of main parts

| Part Name | Material | |||

| Body | WCB | 304(CF8) | 316(CF8M) | 316L(CF3M) |

| Ball | 2Cr13+Nitriding treatment | 304 | 316 | 316L |

| Stem | 2Cr13 | 304 | 316 | 316L |

| Seat seal | PTFE, PPL, Metal Seal (Carbide) | |||

| Packing | V-type PTFE tetrafluoro packing, flexible graphite | |||

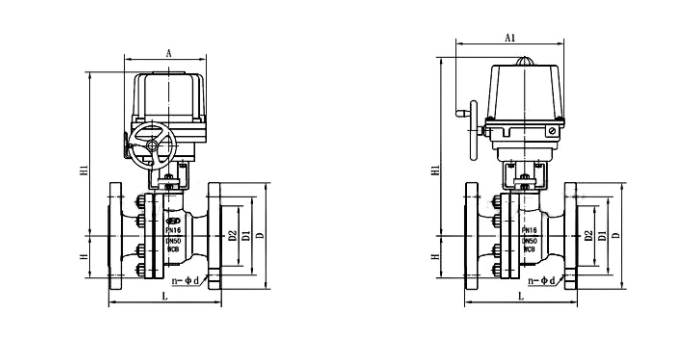

Main external connection dimensions

DN(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 |

H | 44.5 | 49 | 55 | 65 | 65 | 75 | 90 | 95 | 115 | 127 | 140 | 172.5 | 310 | 350 |

H1 | Depends on the model of the actuator | |||||||||||||

D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 |

D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

D2 | 46 | 56 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 |

n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 |

A、A1 | According to the torque required by the valve, the configuration models are different, and the external dimensions are also different. | |||||||||||||