Electric forged high pressure gate valve

Technical Parameter

Product Model: Z960(2)Y

Nominal diameter: DN150-225

Nominal pressure: PN320/420

Applicable medium: water, oil, steam, acid, alkali, ammonia, urea, sulfur, natural gas, etc.

Applicable temperature: -29℃~550℃

Body material: forged steel A105, A182, F22

Drive mode: electric

Connection method: welding

Product Description

The electric forged high pressure gate valve is suitable for cutting off or connecting the pipeline medium on the pipelines of various systems of petroleum, chemical, hydraulic and thermal power stations with nominal pressure PN320/420 and working temperature ≤-29℃~550℃. Applicable media are: water, oil, steam, acid, alkali, ammonia, urea, sulfur, natural gas, etc.

Product Features

1. The selection of materials is exquisite, in line with relevant domestic and foreign standards, and the overall quality of materials is high.

2. It meets the requirements of domestic and foreign standards, with reliable sealing, excellent performance and beautiful appearance.

3. The matching of sealing pairs is reasonable. The sealing surfaces of the gate and valve seat are made of Stellite cobalt-based hard alloys with different hardnesses. The sealing is reliable, high hardness, wear resistance, high temperature resistance, corrosion resistance, Good scratch resistance and long life.

4. The valve stem has good corrosion resistance, scratch resistance and wear resistance after quenching and tempering and surface nitriding treatment.

5. The wedge-type elastic ram structure is adopted, the medium and large diameters are provided with thrust bearings, the friction force is small, and it is equipped with an impact manual, which can be opened and closed easily.

6. Various piping flange standards and flange sealing surface forms can be used to meet various engineering needs and user requirements.

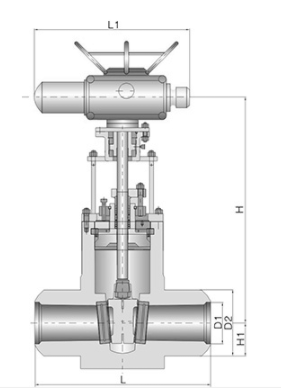

Main external connection dimensions

Model Z960(2)Y-320(forging) | ||||||||

DN | L | H | H1 | L1 | D1 | D2 | Piping size | WT(kg) |

150 | 700 | 1270 | 175 | 985 | 164 | 198 | φ194×15 | 509.7 |

175 | 750 | 1353 | 230 | 946 | 186 | 225 | φ219×16 | 786 |

225 | 850 | 1368 | 220 | 946 | 232 | 275 | φ273×20 | 795 |

Model Z960(2)Y-420(forging) | ||||||||

DN | L | H | H1 | L1 | D1 | D2 | Piping size | WT(kg) |

225 | 850 | 1350 | 230 | 1030 | 221 | 275 | φ273×26 | 1097 |

Model Z960(2)Y-P54 140V(forging) | ||||||||

DN | L | H | H1 | L1 | D1 | D2 | Piping size | WT(kg) |

150 | 700 | 1270 | 175 | 946 | 158 | 198 | φ194×15 | 510 |

225 | 850 | 1368 | 220 | 946 | 232 | 278 | φ273×20 | 795 |

Model Z960(2)Y-P57 170V(forging) | ||||||||

DN | L | H | H1 | L1 | D1 | D2 | Piping size | WT(kg) |

175 | 750 | 1358 | 230 | 946 | 179 | 222 | φ219×20 | 786 |

225 | 850 | 1350 | 230 | 1013 | 221 | 275 | φ273×26 | 1097 |