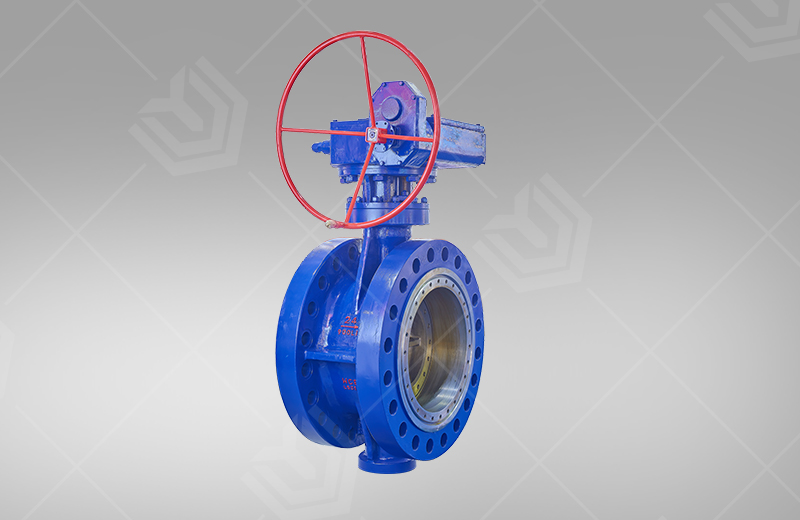

Electric O-type shut-off ball valve

Technical Parameter

Valve model: Q947F/H

Nominal diameter: DN25~300mm

Pressure range: PN1.6~4.0MPa

Operating temperature: -29℃~200℃

Applicable media: syrup, fiber, granules, pulp

Flange standard: GB/T9113-2010

Structural form: floating ball valve

Valve material: stainless steel CF8

Drive mode: electric, intelligent, adjustable

Product Description

Electric O-type cut-off ball valve is a commonly used cut-off valve on modern industrial pipelines. It is assembled by an intelligent electric actuator and an O-type ball valve, and the ball core is an O-type through hole. When working, the ball center and the sealing ring rotate without gap, and the O-shaped ball core has a good shearing force when it is closed. It is especially suitable for syrup, fiber, granule, pulp and some pipelines with viscous media. The working principle is to complete the cut-off and adjustment of the ball valve by driving the (220V, 380V) power supply voltage and accepting (4-20mA) industrial signals to push the valve stem to drive the opening of the ball center to rotate (0~90°). It is usually suitable for occasions with strict sealing requirements, and is widely used in automatic control in chemical, petroleum, pharmaceutical, light industry and other industries.

Product Features

1. The switch action of the electric cut-off ball valve is in place quickly, and the opening and closing action can be completed quickly.

2. Easy to operate, only need to rotate 90 degrees from fully open to fully closed, which is convenient for long-distance control.

3. The circulation capacity is large, and there is basically no flow resistance when fully open.

4. The electric O-type cut-off ball valve has a wide range of applicability, and different connection methods and sealing rings of different materials can be selected to meet different working conditions.

5. It has a good self-cleaning function, which can easily cut off various impurities in the pipeline and effectively ensure the smooth flow of the pipeline.

The main technical parameters

| DN | DN25~DN300(mm) | ||

| PN | PN1.0、1.6、2.5、6.4MPa | ||

| Connection Type | Flange | ||

| Connection Type | Power drive (optional explosion-proof type, with manual device) | ||

| Voltage | AC220V、AC380V(Other custom DC24) | ||

| Spool form | O-type ball spool | ||

| Leakage | Soft seal: zero leakage, hard seal: ≤ 10-5 of rated flow | ||

| Action time | 8~30(DN15-50) 36~60(DN65-300)customizable | ||

| Body Material | Carbon steel, stainless steel304、316、316L | ||

| Flow characteristics | Approximate quick opening characteristics | ||

| Proper temperature | Soft seal -40℃~-180℃; Hard seal -40℃~-450℃ | ||

| Control method | Switch type (two-position switch off), passive contact signal, potentiometer feedback | ||

Material of main parts

| Part Name | Material | |||

| Body,bonnet | WCB | 304(CF8) | 316(CF8M) | 316L(CF3M) |

| Ball | 2Cr13+Nitriding treatment | 304 | 316 | 316L |

| Stem | 2Cr13 | 304 | 316 | 316L |

| Sealing ring | PTFE、PPL、Para-Polyphenylene Flexible Graphite | |||

| Applicable media | Liquid, gas, steam, oil and other corrosive media, etc. | |||

Main external connection dimensions

| DN(mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 | |

| H | match HR | 287 | 312 | 312 | 325 | 335 | 365 | 400 | 420 | 440 | 470 | 545 | 580 |

| match 361R | 380 | 392 | 392 | 415 | 425 | 445 | 490 | 510 | 530 | 560 | 635 | 670 | |

| W | 157 | 157 | 208 | 208 | 256 | 256 | 256 | 256 | 256 | 256 | 380 | 380 | |

| PN1.6MPa | |||||||||||||

| D | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | |

| D2 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | |

| n-φd | 4-14 | 4-18 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | |

| PN2.5MPa | |||||||||||||

| D | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 360 | 425 | 485 | |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | |

| D2 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 274 | 330 | 389 | |

| n-φd | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-26 | 12-30 | 16-30 | |

| PN4.0MPa | |||||||||||||

| D | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 375 | 450 | 515 | |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 320 | 385 | 450 | |

| D6 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-30 | 12-22 | 16-33 | |

| PN6.3MPa | |||||||||||||

| D | 140 | 155 | 170 | 180 | 205 | 215 | 250 | 295 | 345 | 415 | 470 | 530 | |

| D1 | 100 | 110 | 125 | 135 | 160 | 170 | 200 | 240 | 280 | 345 | 400 | 460 | |

| D6 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-18 | 4-22 | 4-22 | 4-22 | 8-22 | 8-22 | 8-26 | 8-30 | 8-33 | 12-36 | 12-36 | 16-36 | |