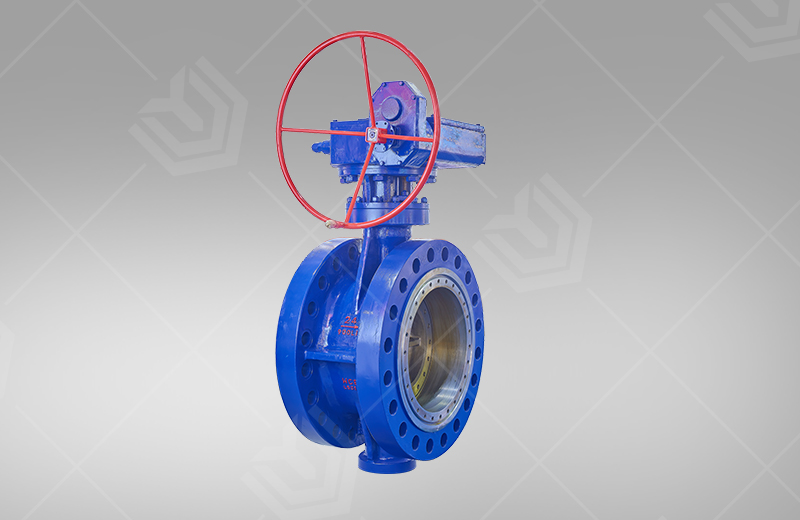

Electric V-type wafer ball valve

Technical Parameter

Product model: VQ977H/Y/F

Nominal diameter: DN25mm~DN300mm

Pressure range: PN 1.0MPa~4.0MPa

Operating temperature: -29℃~200℃

Applicable medium: pulp, fiber, syrup, pulp

Structural form: fixed one

Body material: stainless steel, CF8

Connection method: Wafer connection

Drive mode: electric, switch type, adjustment type

Product Description

Electric V-type wafer ball valve is a commonly used product among many types of ball valves. It can not only be used as the adjustment of the flow medium, but also can be used to cut off and switch. The electric V-type wafer ball valve is mainly composed of a fine and small electric actuator and a V-type wafer ball valve. The structure of the ball valve is a fixed one-piece side installation, which is characterized by a unique V-shaped notch in the design of the ball center. It has good shear strength and self-cleaning function. The ball core and the valve seat rotate without clearance to ensure the sealing of the valve. The electric V-type wafer ball valve is driven by (220V, 380V) power supply, accepts (4~20mA) industrial signals, and drives the valve stem to drive the ball center to rotate to complete the ball valve switch. The V-type wafer ball valve is especially suitable for switching and cutting off and regulating the medium in the pipelines of syrup, fiber, pulp, solid particles and viscous liquid.

Product Features

1. The V-type wafer ball valve has an integrated side-mounted structure with strong toughness and is not easy to cause deformation and leakage. Equipped with upper and lower self-lubricating bearings, the bearing capacity is high, the friction is small, and the torque of the valve is reduced.

2. Due to the shear force between the V-shaped opening and the valve seat, and the smoothness and roundness of the flow passage in the valve cavity, the ball valve can be applied to the system control of pulp, fiber, syrup, solid particles and other media.

Main Part Material

Part Name | Material | |

Valve Body, Valve cover | WCB | CF 8 |

Sealing Ring | 2Cr13+ Nitriding | 304+Nitriding |

Spheroid | 2Cr13+ Hard Steel | 304+Hard Steel |

Valve Seat, Valve Stem | 2Cr13 | 304 |

Gasket | Flexible Graphite + Stainless Steel | Flexible Graphite + Stainless Steel |

Stud | 35CrMoA | 1Cr18Ni9Ti |

Main Performance Specifications

PN | Test pressure(MPa) | Applicable media | Proper temperature | |

Shell test | Seal test | |||

1.6 | 2.4 | 1.76 | Water, oil, gas and high-viscosity media containing fibers, solid particles, etc. | -28℃~≤550℃ |

2.5 | 3.75 | 2.75 | ||

4.0 | 6.0 | 4.4 | ||

Main External Connection Dimensions

PN | DN | Size(mm) | ||||||||

(mm) | (in) | W | L | W1 | L1 | d | d1 | H1 | H | |

PN1.6MPa | 25 | - | 50 | - | 25 | - | 64 | 38 | 57 | 200 |

40 | - | 60 | - | 25 | - | 82 | 49 | 63 | 205 | |

50 | - | 75 | 124 | 32 | 62 | 100 | 60 | 92 | 225 | |

65 | - | 80 | 145 | 38 | 72.5 | 120 | 75 | 100 | 235 | |

80 | - | 100 | 165 | 45 | 82.5 | 131 | 89 | 108 | 260 | |

100 | - | 115 | 194 | 50 | 97 | 158 | 113 | 117 | 270 | |

125 | - | 135 | 210 | 55 | 105 | 180 | 140 | 140 | 320 | |

150 | - | 160 | 229 | 65 | 114.5 | 216 | 164 | 177 | 340 | |

200 | - | 200 | 243 | 80 | 121.5 | 268 | 205 | 200 | 390 | |

250 | - | 240 | 297 | 90 | 148.5 | 326 | 259 | 252 | 420 | |

300 | - | - | 338 | - | 169 | - | 300 | 270 | 510 | |

PN2.5MPa | 25 | - | 50 | - | 25 | - | 64 | 38 | 57 | 200 |

40 | - | 60 | - | 25 | - | 82 | 49 | 63 | 205 | |

50 | - | 75 | 124 | 32 | 62 | 100 | 60 | 92 | 225 | |

65 | - | 85 | 145 | 38 | 72.5 | 120 | 75 | 100 | 235 | |

80 | - | 100 | 165 | 45 | 82.5 | 131 | 89 | 108 | 260 | |

100 | - | 115 | 194 | 50 | 97 | 158 | 113 | 117 | 270 | |

125 | - | 135 | 210 | 55 | 105 | 180 | 140 | 140 | 320 | |

150 | - | 160 | 229 | 65 | 114.5 | 216 | 164 | 177 | 340 | |

200 | - | 200 | 243 | 80 | 121.5 | 268 | 205 | 200 | 390 | |

250 | - | 240 | 297 | 92 | 148.5 | 326 | 259 | 252 | 420 | |

300 | - | - | 338 | - | 169 | - | 300 | 270 | 510 | |

ClASS150 | 25 | - | 50 | - | 25 | - | 64 | 38 | 57 | 200 |

40 | 1-1/2 | 65 | - | 25 | - | 82 | 49 | 63 | 205 | |

50 | 2 | 75 | 124 | 32 | 62 | 100 | 60 | 92 | 225 | |

65 | 2-1/2 | 85 | 145 | 38 | 72.5 | 120 | 75 | 100 | 235 | |

80 | 3 | 100 | 165 | 45 | 82.5 | 131 | 89 | 108 | 260 | |

100 | 4 | 115 | 194 | 50 | 97 | 158 | 113 | 117 | 270 | |

125 | 5 | 135 | 210 | 55 | 105 | 180 | 140 | 140 | 320 | |

150 | 6 | 160 | 229 | 65 | 114.5 | 216 | 164 | 177 | 340 | |

200 | 8 | 200 | 243 | 80 | 121.5 | 268 | 205 | 200 | 390 | |

250 | 10 | 240 | 297 | 92 | 148.5 | 326 | 259 | 252 | 420 | |

300 | 12 | - | 338 | - | 169 | - | ||||