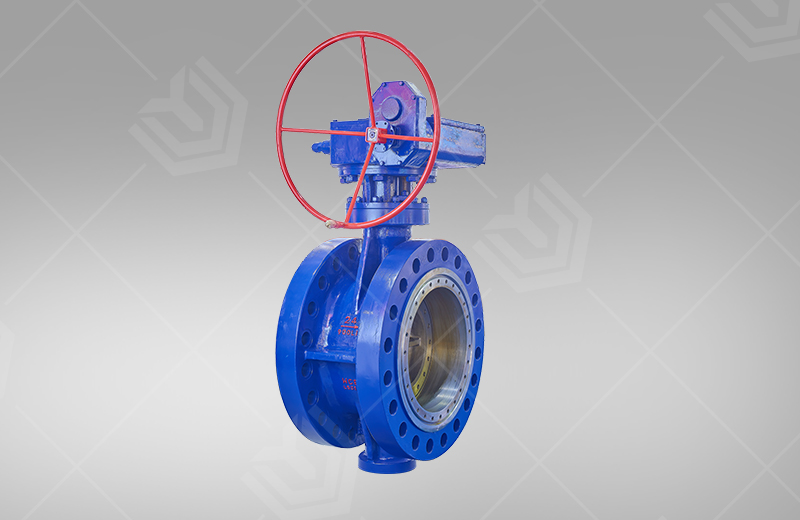

Electric stainless steel floating ball valve

Technical Parameter

General model: Q941F/W

Nominal diameter: DN15~300mm

Pressure range: PN1.6MPa~6.4MPa

Operating temperature: -29℃~200℃

Applicable medium: gas, water, solvent, weak acid

Flange standard: GB/T9113-2010

Structural form: floating straight-through

Body Material: Stainless Steel CF8

Drive mode: electric, adjustment type, switch type

Product Description

Electric stainless steel floating ball valve is assembled by intelligent electric actuator and stainless steel ball valve, and adopts soft sealing structure. The flow channel of the ball valve is a straight-through type, with small flow resistance, strong flow capacity and less medium retention. The ball center of the ball valve is made of stainless steel, which is made smooth by fine grinding, and rotates with the sealing surface without clearance when opening and closing to ensure the sealing performance of the valve. By using the (220V, 380V) power supply voltage as the drive to receive (4-20mA) industrial signals, the valve stem is driven to drive the rotation of the ball center to achieve switching and adjustment. Mainly used in natural gas, clean water, solvent, weak acid, slightly corrosive gas, liquid and other pipelines as the switch and adjustment of medium flow.

Product Features

1. The fluid resistance is small. The ball valve is the one with the smallest fluid resistance among all valves. Even the reduced diameter ball valve has a relatively small fluid resistance.

2. The thrust bearing reduces the friction torque of the valve stem, and the valve stem can be used for long-term operation balance and flexibility.

3. The valve seat has good sealing performance. The sealing ring made of PTFE and other materials is easy to seal in structure, and the sealing ability of the ball valve increases with the increase of the pressure of the medium.

4. The valve stem is sealed reliably. Since the valve stem only rotates and does not move up and down, the packing seal of the valve stem is not easy to be damaged, and the sealing capacity increases with the increase of the pressure of the medium.

5. Because the PTFE material has good self-lubrication, the friction loss with the ball is small, and the service life of the ball valve is long.

6. The bottom-mounted valve stem and the convex step on the head of the valve stem prevent the valve stem from being ejected. If the valve stem seal is damaged due to fire, the convex step and the valve body can also form metal contact to ensure the valve stem seal.

The Main Technical Parameters

| DN(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Kv | 21 | 38 | 72 | 112 | 170 | 273 | 384 | 512 | 940 | 1452 | 2222 | 3589 | 5128 | 7359 |

| PN(MPa) | PN1.6、2.5、4.0、6.4MPa | |||||||||||||

| Leakage | Soft seal: zero leakage | |||||||||||||

| Body form | Two-section valve body (floating ball) | Two-stage valve body (fixed ball) | ||||||||||||

| Spool form | "O" ball valve core | |||||||||||||

| Seal packing | Polytetrafluoroethylene (PTFE), metal graphite spiral wound gasket | |||||||||||||

| Connection Type | Flanged, Welded, Threaded | |||||||||||||

| Flow characteristics | Approximate quick opening characteristics | |||||||||||||

| Adjustable range | DN15-65 | DN80-300 | ||||||||||||

| 250:1 | 350:1 | |||||||||||||

| Basic error | ±1% | |||||||||||||

| Dead zone | ≤1% | |||||||||||||

| Return difference | ≤1% | |||||||||||||

| proper temperature | Sealing surface | |||||||||||||

| PTFE≤180℃、PPL≤280℃ | ||||||||||||||

| Configure the actuator | Can be equipped with PSQ, HQ, UNIC, 361RS, HR and other series of angular stroke electric actuators | |||||||||||||

| Control method | Switch in-position light (switch two-position control), intelligent adjustment (4-20mA analog signal control) | |||||||||||||

Main Performance Specifications

| DN(mm) | DN15-300 | ||||

| PN | PN(MPa) | 1.6 | 2.5 | 4.0 | 6.4 |

| Test pressure | Strength test | 15.0 | 24.0 | 37.5 | 48.0 |

| Seal test | 11.0 | 17.6 | 27.5 | 35.2 | |

| Low pressure air tightness test | 0.5~0.7 | ||||

| Applicable media | Water, oil, steam, nitric acid (temperature≤200℃), acetic acid (temperature≤200℃) | ||||

Material Of Main Parts

| Part Name | Material | |||

| Valve body | WCB | 304(CF8) | 316(CF8M) | 316L(CF3M) |

| Spheroid | 2Cr13+Nitriding treatment | 304 | 316 | 316L |

| Stem | 2Cr13 | 304 | 316 | 316L |

| Seat seal | PTFE、PPL | |||

| Filler | V-type PTFE, flexible graphite | |||

Main External Connection Dimensions

| DN(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 | |

| H | Match PSQ | 275 | 280 | 287 | 312 | 312 | 325 | 335 | 365 | 400 | 420 | 440 | 470 | 545 | 580 |

| Match HQ | 360 | 370 | 380 | 392 | 392 | 415 | 425 | 445 | 490 | 510 | 530 | 560 | 635 | 670 | |

| Match 361R | 360 | 370 | 380 | 392 | 392 | 415 | 425 | 445 | 490 | 510 | 530 | 560 | 635 | 670 | |

| W | 157 | 157 | 157 | 157 | 208 | 208 | 256 | 256 | 256 | 256 | 256 | 256 | 380 | 380 | |

| PN1.6MPa | |||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | |

| D2 | 46 | 56 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | |

| PN2.5MPa | |||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 360 | 425 | 485 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | |

| D2 | 46 | 56 | 65 | 76 | 84 | 99 | 118 | 132 | 156 | 184 | 211 | 274 | 330 | 389 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-26 | 12-30 | 16-30 | |

| PN4.0MPa | |||||||||||||||

| D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 235 | 270 | 300 | 375 | 450 | 515 | |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 320 | 385 | 450 | |

| D6 | 40 | 51 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-22 | 8-26 | 8-26 | 12-30 | 12-22 | 16-33 | |

| PN6.3MPa | |||||||||||||||

| D | 105 | 130 | 140 | 155 | 170 | 180 | 205 | 215 | 250 | 295 | 345 | 415 | 470 | 530 | |

| D1 | 75 | 90 | 100 | 110 | 125 | 135 | 160 | 170 | 200 | 240 | 280 | 345 | 400 | 460 | |

| D6 | 40 | 51 | 58 | 66 | 76 | 88 | 110 | 121 | 150 | 176 | 204 | 260 | 313 | 364 | |

| n-φd | 4-14 | 4-18 | 4-18 | 4-22 | 4-22 | 4-22 | 8-22 | 8-22 | 8-26 | 8-30 | 8-33 | 12-36 | 12-36 | 16-36 | |