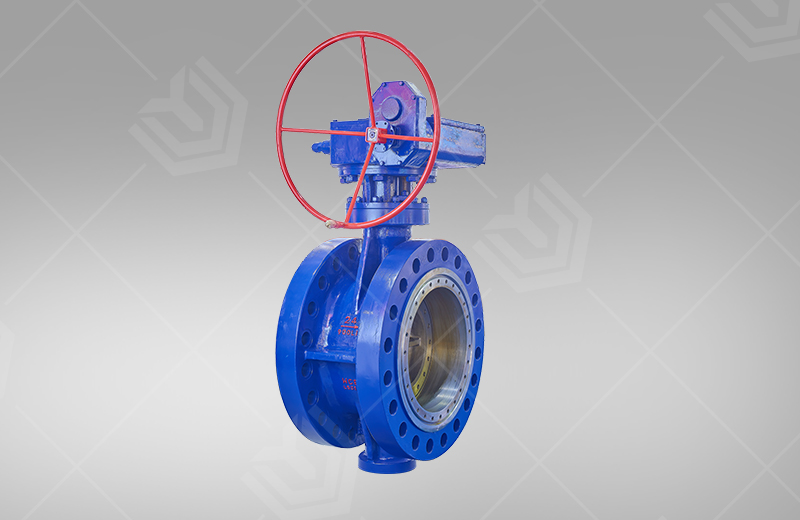

Side- Eccentric Hemisphere Valve(Electric)

Technical Parameter

Product model: PQ940F/Y/H

Nominal diameter: DN100~2000mm

Nominal pressure: PN1.0~6.4MPa

Applicable temperature: -29℃~425℃

Applicable media: pulverized coal, coal ash, dust, gas

Flange connection size: GB/T17241.6,BS4504, ISO7005,DIN2501

Structure length: GB/T26146-2010

Manufacturing and acceptance: GB12237-89, API 6D

Pressure test: JB/T9092-1999, GB/T13927-92, API98

Product Structure Features:

1、More reasonable structure design

Adopting the eccentric deed principle achieves the purpose of the brake tightly, regulation by transmission mechanism. The sealing ring surface is metal with hard faced contact seal. Double eccentric structure is in the open when the valve core is located in the ball room.large flow area and zero water loss, can save a lot of resources, and the valve is not washed. close the valve core will not be washed,and open the valve core sphere can effectively move along the seat, so as to easily remove fouling obstacles, achieve reliable seal,and the two-phase mixed flow easily scale solid precipitation mixed flow convey particularly effectively.

2、Lower pressure loss

Fully open when the water loss is zero, the flow channel is completely smooth; chest automatic cleaning.,The valve core is can rotate in 90 angle,automatically flush valve chest and clean up the debris of the medium. ) Also, the debris will not be deposited in the valve chest . The ball is hemispherical. Circulation with the highest Cv value enhanced the system efficiency of the pump and the abrasion is reduced to the lowest degree.

3、Better quality assurance of sealing

Using eccentric principle, the ball and valve seat are closed tightly under the positive pressure, so as to obtain good sealing; floating seat under the anti pressure, will push the ball towards valve seat. The higher the pressure, the closer between valve seat and the ball, So that the sealing can get a good automatic seal function.

4、Longer service life

No wearing parts. Due to the eccentric effect, in the process of opening and closing, the valve body completely separated from the sealing of valve seat, and make the seat surface and the spherical cap shift without friction between spherical rotation. At the same time it can reduce operating torque effectively and operate easily. Automatic compensation functions of the valve, can greatly improve the service life of the valve.

5、Maintenance easier

Self-cleaning function. When the ball roll away from the valve seat, fluid in the pipeline flow along the sealing surface of the sphere into 360 degree, not only eliminates the high-speed fluid scour to seat local, sediment is washed away from the sealing face. The spherical cap edge with hard seal eccentric semi ball valve adopts edge shape, not only can scrape the dirt on the valve seat, also can cut sundries, to achieve self cleaning purposes.

Material Of Main Parts

NO | Part Name | Material name | |||

1 | Body/bonnet | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ZG15Cr1Mo1V |

2 | Spheroid | WCB+Hard Chrome | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr2Mo1V |

3 | Stem | 20Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr2Mo1V |

4 | Valve seat | Q235A+PTFE/堆焊 | 1Cr18Ni9Ti/PTFE | 0Cr18Ni12Mo2Ti/PTFE | 25Cr2Mo1V/PTFE |

5 | Filler | Flexible graphite | Flexible graphite | Flexible graphite | Flexible graphite |

6 | Bolt | 35CrmoA | 0Cr18Ni9 | 0Cr18Ni9 | 15Cr1Mo1V |

7 | Nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 20CrMo |

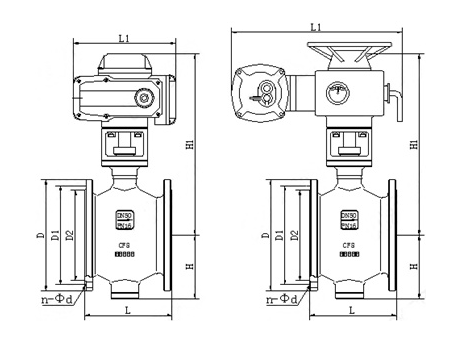

Main External Connection Dimensions

PN(MPa) | DN | Size(mm) | ||||||||

L | D Series 1/Series 2 | D1 | D2 | D6 | b | f | Z-φd | |||

mm | in | Flange | ||||||||

1.0 | 40 | - | 125 | 145 | 110 | 85 | - | 16 | 3 | 4-18 |

50 | - | 140 | 160 | 125 | 100 | - | 16 | 3 | 4-18 | |

65 | - | 190 | 180 | 145 | 120 | - | 18 | 3 | 4-18 | |

80 | - | 178 | 195 | 160 | 135 | - | 20 | 3 | 4-18 | |

100 | - | 200 | 215 | 180 | 155 | - | 20 | 3 | 8-18 | |

125 | - | 254 | 245 | 210 | 185 | - | 22 | 3 | 8-18 | |

150 | - | 267 | 280 | 240 | 210 | - | 24 | 3 | 8-23 | |

200 | - | 292 | 335 | 295 | 265 | - | 24 | 3 | 8-23 | |

250 | - | 330 | 390 | 350 | 320 | - | 26 | 3 | 12-23 | |

300 | - | 390 | 440 | 400 | 368 | - | 26 | 4 | 12-23 | |

350 | - | 430 | 500 | 460 | 428 | - | 28 | 4 | 16-23 | |

400 | - | 530 | 565 | 515 | 482 | - | 28 | 4 | 16-25 | |

450 | - | 580 | 615 | 565 | 532 | - | 30 | 4 | 20-25 | |

500 | - | 630 | 670 | 620 | 585 | - | 30 | 4 | 20-25 | |

600 | - | 800 | 480 | 725 | 685 | - | 34 | 5 | 20-30 | |

700 | - | 900 | 895 | 840 | 800 | - | 38 | 5 | 24-30 | |

800 | - | 1000 | 1010 | 950 | 905 | - | 42 | 5 | 24-34 | |