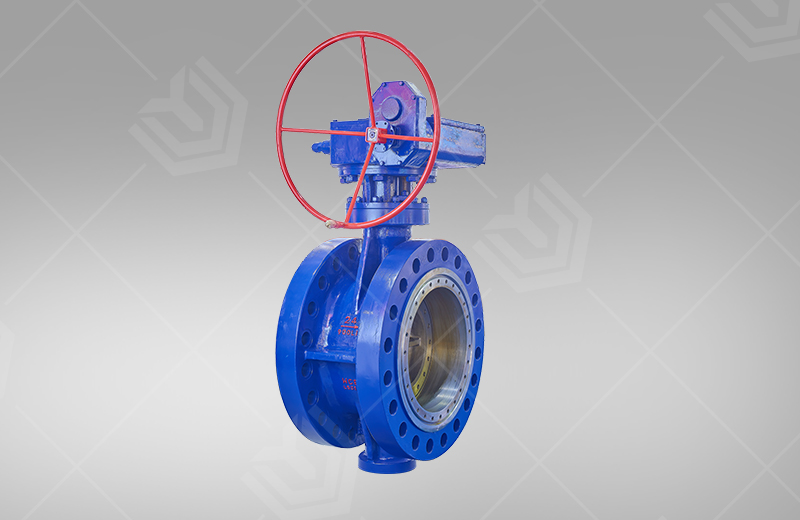

Pneumatic Flanged Eccentric Butterfly Valve

Technical Parameter

Item model number: D642X

Nominal diameter: DN50~2000mm

Nominal pressure: PN0.6~1.6MPa

Working temperature: Rubber: -40℃~90℃, Fluorine rubber: -20℃~200℃

Applicable medium: water, air, natural gas, oil and weak corrosive fluid

Manufacturing standard: GB/T 122387

Flange standard: GB/T 9113, GB/T17241.6

Structure length: GB/T 12221

Inspection standard: GB/T 13927

Product overview

Pneumatic double eccentric flange butterfly valve is suitable for water system, power plant and industrial pipeline as two-way opening and closing and adjustment equipment. Its compact structure, easy 90° rotary switch, reliable sealing and long service life. The disc of this series of butterfly valves is designed with a flow-through double-plate truss structure and made of high-strength ductile iron to ensure the strength of the disc under the impact of water flow and lower water loss. It is widely used in water supply and drainage of water plants, power plants, steel mills, papermaking, chemical industry, food and beverage systems, etc., as regulation and cut-off use.

Features

1. The valve adopts double eccentric structure, which has the sealing function of tighter and tighter, and the sealing performance is reliable.

2. The sealing material is made of stainless steel and oil-resistant rubber, which has a long service life.

3. The rubber sealing ring can be located on the valve body or on the butterfly plate, and can be applied to media with different characteristics for users to choose.

4. The butterfly plate adopts frame structure, which has high strength, large flow area and small flow resistance.

5. The overall paint can effectively prevent corrosion and can be used for different media as long as the sealing material of the sealing valve seat is replaced.

6. The valve has a two-way sealing function. It is not controlled by the flow direction of the medium during installation, nor is it affected by the spatial position. It can be installed in any direction.

7. The valve has a unique structure, flexible, labor-saving and convenient operation.

The main technical parameters

Nominal diameter DN(mm) | 50~2000 | 50~1600 | |

Nominal pressure PN(MPa) | 0.6 | 1.0 | 1.6 |

Seal test(MPa) | 0.66 | 1.1 | 1.76 |

Strength test(MPa) | 0.9 | 1.5 | 2.4 |

Proper temperature | Rubber: -40℃~90℃, Fluorine rubber: -20℃~200℃ | ||

Applicable media | Water, air, natural gas, oil and weak corrosive fluids | ||

Leak rate | Comply with GB/T13927-92 standard | ||

Drive mode | Pneumatic | ||

Material of main parts

Part Name | Material |

Body | WCB、QT450-10、HT200、HT250 |

Disc | WCB、QT450-10、HT200、HT250 |

Valve shaft | 2Cr13 |

Sealing ring | Oil resistant rubber |

Packing | Flexible graphite |

Main external connection dimensions

Nominal diameter DN (mm) | Main external connection dimensions | Flange size and bolt hole size | |||||||||||||||

L | H | H1 | A | B | 0.6MPa | 1.0MPa | 1.6MPa | ||||||||||

D | D1 | D2 | n-d | D | D1 | D2 | n-d | D | D1 | D2 | n-d | ||||||

50 | 108 | 82.5 | 338 | 180 | 65 | 140 | 110 | 88 | 4-14 | 185 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

65 | 112 | 92.5 | 358 | 180 | 65 | 160 | 130 | 108 | 4-14 | 185 | 145 | 118 | 4-18 | 185 | 145 | 118 | 4-18 |

80 | 114 | 100 | 413 | 245 | 72 | 190 | 150 | 124 | 4-18 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

100 | 127 | 110 | 428 | 240 | 72 | 210 | 170 | 144 | 4-18 | 220 | 180 | 156 | 8-18 | 220 | 180 | 156 | 8-18 |

125 | 140 | 125 | 444 | 240 | 72 | 240 | 20 | 174 | 8-18 | 250 | 210 | 184 | 8-18 | 250 | 210 | 184 | 8-18 |

150 | 140 | 142.5 | 553 | 350 | 93 | 265 | 225 | 199 | 8-18 | 285 | 240 | 211 | 8-22 | 285 | 240 | 211 | 8-22 |

200 | 152 | 170 | 678 | 350 | 93 | 320 | 280 | 254 | 8-18 | 340 | 295 | 266 | 8-22 | 340 | 295 | 266 | 12-22 |

250 | 165 | 192.5 | 742 | 550 | 350 | 375 | 335 | 309 | 12-18 | 395 | 350 | 319 | 12-22 | 405 | 355 | 319 | 12-26 |

300 | 178 | 222.5 | 803 | 600 | 350 | 440 | 395 | 363 | 12-22 | 445 | 400 | 370 | 12-22 | 460 | 410 | 370 | 12-26 |

350 | 190 | 252.5 | 866 | 600 | 350 | 490 | 445 | 413 | 12-22 | 505 | 460 | 429 | 16-22 | 520 | 470 | 429 | 16-26 |

400 | 216 | 282.5 | 940 | 600 | 350 | 540 | 495 | 463 | 16-22 | 565 | 515 | 480 | 16-26 | 580 | 525 | 480 | 16-30 |

450 | 222 | 307.5 | 995 | 750 | 380 | 595 | 550 | 518 | 16-22 | 615 | 565 | 530 | 20-26 | 640 | 585 | 548 | 20-30 |

500 | 229 | 335 | 1058 | 750 | 380 | 645 | 600 | 568 | 20-22 | 670 | 620 | 582 | 20-26 | 715 | 650 | 609 | 20-33 |

600 | 267 | 390 | 1163 | 750 | 380 | 755 | 705 | 667 | 20-26 | 780 | 725 | 682 | 20-30 | 840 | 770 | 720 | 20-36 |

700 | 292 | 447.5 | 1283 | 750 | 380 | 860 | 810 | 772 | 24-26 | 895 | 840 | 794 | 24-30 | 910 | 840 | 794 | 24-36 |

800 | 318 | 507.5 | 1398 | 750 | 380 | 975 | 920 | 878 | 24-30 | 1015 | 950 | 901 | 24-33 | 1025 | 950 | 901 | 24-39 |

900 | 330 | 557.5 | 1498 | 1250 | 380 | 1075 | 1020 | 978 | 24-30 | 1115 | 1050 | 1001 | 28-33 | 1125 | 1050 | 1001 | 28-39 |

1000 | 410 | 615 | 1608 | 1500 | 580 | 1175 | 1120 | 1078 | 28-30 | 1230 | 1160 | 1112 | 28-36 | 1255 | 1170 | 1112 | 28-42 |

1200 | 470 | 727.5 | 1876 | 1500 | 580 | 1405 | 1340 | 1295 | 32-33 | 1455 | 1380 | 1328 | 32-39 | 1485 | 1390 | 1328 | 32-48 |