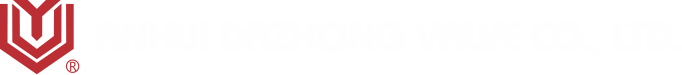

Pneumatic high performance butterfly valve

Technical Parameter

Product model: 815W/L-P, 830W/L-P

Nominal diameter: DN65~700mm, NPS 2-1/2"~28"

Nominal pressure: CL150~300LB

Applicable medium: gas, water and oil, etc.

Applicable temperature: -30~+150℃

Working temperature: -20~80℃

Connection form: clip

Main material: 304, 316, carbon steel

Product overview

The pneumatic high-performance butterfly valve has a unique product structure and a floating seat design. According to the direction of the pressure source, the seat position is automatically adjusted to achieve the double-sided pressure-sustaining sealing effect of the valve and increase the service life of the valve seat. The valve shaft is specially designed for dust prevention to prevent fluid from entering the valve shaft and causing the valve shaft to be stuck. Different materials and properties can be selected according to different working conditions. The valve seat is made of PTFE, RTFE, PEEK, METAL and other materials. Pneumatic high-performance butterfly valve is suitable for petrochemical, oil refining, air separation, CDA and other working conditions.

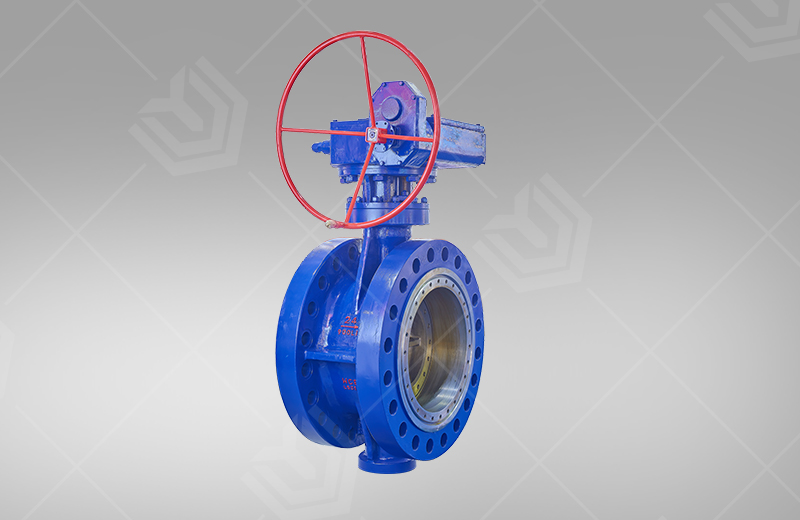

The valve is widely used in the transportation of liquids and gases (including steam) in various industrial pipelines. It can also be used for special media such as oxygen, high vacuum, sulfur-resistant or corrosive media. The product can also have a fireproof structure as an option. The connection method can be a wafer type or a lug type single flange design for large pipe diameters and pipeline terminals.

Features

1. Unique structure, double-sided pressure holding design;

2. Reliable sealing;

3. A full range of anti-static guiding device structure, ultra-small operating torque;

4. The strength of the valve conforms to: ASME B16.34, API 598;

5. The full caliber has passed the API 607 fire test regulations;

6. Metal valve seat leakage conforms to ANSI FCI 70-2-2003 Table 1 CLASS IV;

7. Valve shaft escape meets EPA Method 21 test;

8. The connection methods include wafer type and single flange type.

Main performance parameters

Valve series | Design form | Pressure level | Size(in) | Applicable temperature ℃ | Shell material | Adopt standard |

815W series | Wafer type | 150LB | 2-1/2~30 | -29~+260 (Carbon Steel Body) -46~+260 (Stainless Steel Body) | WCB carbon steel CF8M Monel | API 609 |

815L series | Lug | 2-1/2~60 | ||||

830W series | Wafer type | 300LB | 3~24 | |||

830L series | Lug | 3~36 |

The main technical parameters

Drive air source | Compressed air 5~7bar (with handwheel) |

Nominal diameter | 65~700mm |

Nominal pressure | 150~300LB |

Proper temperature | -30~+150℃ |

Connection method | Wafer type |

Body structure | Two eccentric, three eccentric |

Body Material | 304, 316, carbon steel |

Disc material | 304、316 |

Sealing material | PTFE (customizable reinforced PTFE) |

Applicable media | Gas, water and oil, etc. |

Optional accessories | Limit switches, positioners, solenoid valves, pressure reducing valves |

Main external dimensions

Nominal diameter (mm) | NPS(in) | Size(mm) | ||||

L | L1 | D1 | D | H | ||

65 | 2-1/2 | 49 | 27 | 119 | 59 | 177 |

80 | 3 | 49 | 27 | 132 | 73 | 193 |

100 | 4 | 54 | 30 | 157 | 95 | 212 |

125 | 5 | 64 | 30 | 186 | 111 | 216 |

150 | 6 | 57 | 33 | 216 | 142 | 243 |

200 | 8 | 57 | 36 | 270 | 188 | 299 |

250 | 10 | 71 | 41 | 324 | 236 | 371 |

300 | 12 | 81 | 48 | 381 | 282 | 416 |

350 | 14 | 92 | 52 | 413 | 314 | 494 |

400 | 16 | 102 | 56 | 470 | 363 | 531 |

450 | 18 | 114 | 67 | 533 | 414 | 569 |

500 | 20 | 127 | 67 | 584 | 456 | 604 |

600 | 24 | 154 | 76 | 692 | 549 | 784 |

700 | 28 | 167 | 87 | 857 | 702 | 912 |