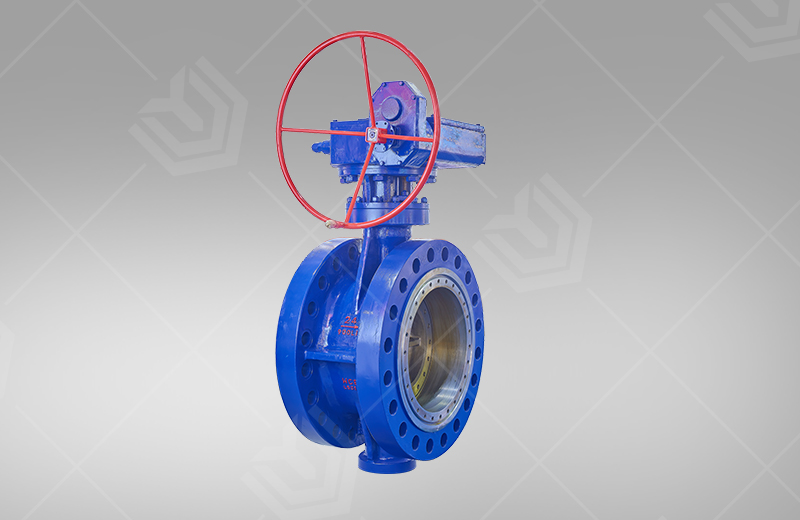

Self-operated pressure regulating valve with pilot

Technical Parameter

General model: ZZYVP-16B

Nominal diameter: DN20~150mm

Pressure range: PN1.0~1.6MPa

Operating temperature: ≤80℃

Manufacturing standard: GB/T4213-1992

Flange standard: GB/T9113-2000

Valve material: WCB, CF8

Adjustment accuracy: (%)≤10

Leakage level: ANSI B16.104-1976 (level IV)

Product Description

Self-operated nitrogen sealing valve (ie nitrogen sealing device) is mainly used for constant control of nitrogen pressure at the top of the storage tank. Self-operated nitrogen sealing valve is a kind of non-external energy source, which uses the spring as the power core and uses the pressure of the adjusted medium to control the valve core The position changes to achieve the purpose of automatic adjustment and stable pressure, so as to protect the material in the tank from being nitrided and the safety of the storage tank. The valve consists of two parts: ZZYVP quick relief valve and ZZV self-operated micro-pressure regulating valve. The quick relief valve is composed of a pressure controller and a ZMQ-16K single-seat shut-off valve.

Working Principle

When the pressure in the storage tank rises to the set pressure, the quick relief valve opens quickly to release the excess pressure in the tank. When the pressure in the storage tank decreases, the micro-pressure regulating valve opens the valve and fills the tank with nitrogen. Because the micro-pressure regulating valve must be used below the pressure of 0.1Mpa, and the on-site pressure is high, the ZZYP type pressure regulating valve must be installed to reduce the pressure to below 0.1Mpa before it can be used. The nominal pressure is 0.1Mpa, and the pressure can be set in sections, from 0.5Kpa to below 66 Kpa, and the temperature of the medium is ≤80℃.

Product Features

1. No additional energy is required, and it can work in places without electricity and gas, which is convenient, saves energy and reduces costs.

2. The nitrogen sealing device can supply nitrogen, and the nitrogen release pressure is convenient to set, which can be carried out under the condition of continuous operation.

3. The effective area of the pressure detection diaphragm is large, the setting spring stiffness is small, the action is sensitive, and the device works well.

4. With the design of no packing, the friction force on the valve stem is small, the response is fast, and the control precision is high.

5. The nitrogen supply device is operated by the pilot, the decompression ratio can reach 100:1, the decompression effect is good, and the control precision is high.

6. The nitrogen pressure setting range is wide, as low as 0.5Kpa and as high as 1000Kpa, with a high ratio;

7. The effective area of the adjusting pressure detection diaphragm is large, the setting spring stiffness is small, and the action is extremely sensitive.

The main technical parameters

DN (mm) | 20 | 25 | 40 | 50 | 80 | 100 | 150 | |||||

Seat Diameter (mm) | 6 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

| Kv | 3.2 | 5 | 8 | 10 | 20 | 32 | 50 | 80 | 100 | 160 | 250 | 400 |

| Pressure adjustment range | 0.5~70 20~120 60~400 300~700 500~1000 KPa | |||||||||||

| PN | 1.0、1.6 MPa | |||||||||||

| Adjusted medium temperature | 80、200 ℃ | |||||||||||

| Flow characteristics | Quick opening | |||||||||||

| Adjustment accuracy | ≤5% | |||||||||||

Allowable pressure drop (MPa) | 1.6 | 1.6 | 1.1 | 0.6 | 0.4 | |||||||

Effective area of film(c㎡) | 200 | 280 | 400 | |||||||||

| Allowable leakage | Comply with ANSIB16.104-1976 Class IV | |||||||||||

| Bonnet form | Standard Type (Integral Type) | |||||||||||

| Gland type | Bolt compression | |||||||||||

| Seal packing | V-type PTFE packing, impregnated PTFE asbestos packing, asbestos textile packing, graphite packing | |||||||||||

| Spool form | Single seat valve core | |||||||||||

| Flow characteristics | Linearity | |||||||||||

Main external connection dimensions

| DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

| L | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 |

| H | 52.5 | 57.5 | 75 | 75 | 85.5 | 92.5 | 100 | 110 | 142.5 | 158 |

| H1 | 330 | 330 | 350 | 350 | 360 | 430 | 440 | 450 | 520 | 650 |

| A | 310 | 400 | ||||||||