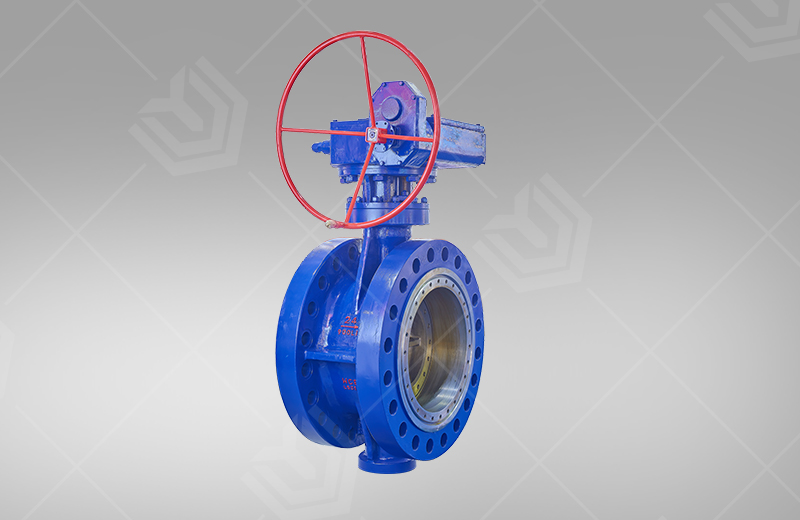

Product Features

1. This valve is a new type of throttling, cut-off and venting product. The valve adopts cage-shaped fan legion throttling, with multi-stage throttling effect, obvious throttling effect, reliable sealing, convenient operation and maintenance, etc.

2. The valve adopts double seals (hard and soft seals) to make the seal reliable, and the hard alloy cover can be more resistant to airflow erosion and wear, and the double seal can achieve zero leakage under the condition of high-pressure gas medium. The valve has a long service life.

3. The sealing surface of the valve seat adopts tapered sealing, which is beneficial to the valve itself to clean the dirt attached to the sealing surface.

4. A balance hole is set on the valve disc of the valve, and the piston seal ensures stable operation under the condition of full pressure difference between opening and closing, light and flexible opening and small opening and closing torque.

5. The throttling cut-off vent valve and the double-acting throttle valve have the functions of throttling and cut-off (zero leakage of the seal) at the same time. The throttling part is separated from the sealing surface to reduce the erosion of the air flow to the seal.

6. The double-acting throttling globe valve also has a multi-stage throttling function, and the throttling pressure difference is large, which can be suitable for throttling and blocking under high pressure.

7. The packing adopts a V-shaped packing structure with self-sealing ability, which does not need to be adjusted, and is extremely easy to open and close. There is an auxiliary sealing grease injection structure at the stuffing box, so that the valve packing sealing performance is reliable.

8. The valve can be repaired online, and the pipeline can be replaced with a series of wearing parts such as packing under pressure.

9. The valve is equipped with a large sewage hole at the bottom of the valve, which should be opened when necessary to clean the dirt in the valve.

Working Principle

1. Normally closed state: The hard seal of the valve disc is pressed on the valve seat boss to form a hard seal, while the soft seal embedded on the valve disc is pressed against the end face of the valve seat to form a second seal, a double-quality seal. The sealing structure ensures zero leakage of the valve, and because the valve disc has a balance hole, the valve disc is subject to less force when the valve is closed and opened, and the valve has a small torque when it is opened and closed.

2. Slow pressure state: When the bottom end of the valve disc leaves the sealing surface of the valve seat, since the bottom end face of the valve disc is close to the bottom edge of the cage sleeve opening, the valve disc and the inner diameter of the cage sleeve form a seal at this time. There is no direct venting and pressure relief, so as to achieve a relaxing effect.

3. Throttling state: the bottom of the valve disc leaves the valve seat and is further opened, a first-level throttling is formed at the small throttle head, and the high-speed fluid flows directly to the small valve disc after being throttled by the slow pressure. On the other hand, when the high-pressure medium directly scours the throttling passage, the bottom end of the valve disc will generate eddy current due to the change of the medium direction, which slows down the direct scouring of the valve disc of the medium, so that the valve seat seal also avoids the direct scouring of the medium. The sealing surface is conical, which can purge the dirt and impurities on the sealing surface of the valve seat, protect the sealing surface, and prolong the service life of the valve.

4. Fully open state: When the valve disc is fully open, the entire valve is in a fully vented state, and the resistance of the fluid in the unpopular is small, which shortens the venting time and improves the venting effect of the valve.

Main external connection dimensions

| PN(MPa) | DN(mm) | size(mm) | WT(kg) | |||

| L | H | H1 | D0 | |||

| 1.6 | 25 | 216 | 243 | 86 | 180 | 18 |

| 40 | 230 | 265 | 108 | 250 | 25 | |

| 50 | 230 | 346 | 115 | 250 | 28 | |

| 80 | 310 | 409 | 146 | 300 | 53 | |

| 100 | 350 | 433 | 163 | 300 | 62 | |

| 150 | 480 | 521 | 202 | 350 | 128 | |

| 200 | 600 | 594 | 292 | 350 | 168 | |

| 250 | 730 | 621 | 355 | 400 | 289 | |

| 2.5 | 25 | 230 | 243 | 86 | 180 | 18 |

| 40 | 230 | 265 | 108 | 250 | 25 | |

| 50 | 230 | 346 | 115 | 250 | 28 | |

| 80 | 310 | 409 | 146 | 300 | 57 | |

| 100 | 350 | 433 | 163 | 300 | 69 | |

| 150 | 480 | 521 | 202 | 350 | 145 | |

| 200 | 600 | 594 | 292 | 350 | 188 | |

| 250 | 730 | 621 | 355 | 400 | 315 | |

| 4.0 | 25 | 216 | 243 | 86 | 180 | 21 |

| 40 | 230 | 265 | 108 | 250 | 31 | |

| 50 | 230 | 346 | 115 | 250 | 35 | |

| 80 | 310 | 409 | 146 | 300 | 70 | |

| 100 | 350 | 433 | 163 | 300 | 85 | |

| 150 | 480 | 521 | 202 | 350 | 172 | |

| 200 | 600 | 594 | 292 | 350 | 219 | |

| 250 | 730 | 621 | 355 | 400 | 378 | |