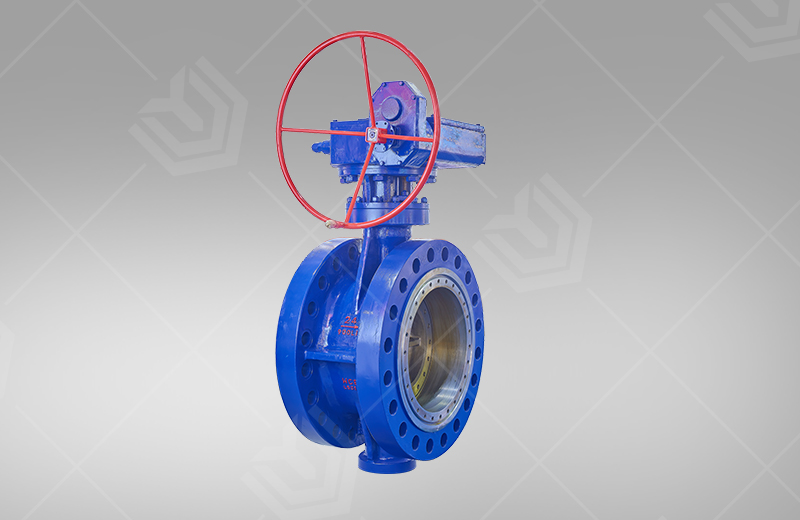

Feedwater rotary control valve

Technical Parameter

Item model number: T40H

Nominal diameter: DN15~DN600

Nominal pressure: PN1.6MPa~10.0MPa

Applicable temperature: -29ºC~+450ºC

Structural form: rotary

Connection method: flange

Drive mode: manual

Body material: gray cast iron, cast steel, stainless steel

Applicable medium: water, steam

Product Description

The feedwater rotary control valve is suitable for medium and low pressure boiler feedwater pipes and high-pressure heater drain pipes. By rotating the cylindrical valve disc to change the area of the window formed by the valve seat, the purpose of regulating flow is achieved. The rotary opening and closing angle of the water supply rotary control valve is 60°, which is indicated by the opening indicator plate above the control valve. It can be equipped with electric actuators for remote automatic operation.

Main Performance Parameters

Model | Work pressure(MPa) | Proper temperature(℃) | Applicable media | Material | |

T40H-16 | 1.6 | ≤200 | Water, steam | Grey cast iron | Stainless steel |

T40H-25 | 2.5 | ≤450 | Cast steel | ||

T40H-40 | 4.0 | ||||

T40H-64 | 6.4 | ||||

T40H-100 | 10.0 | ||||

Material Of Main Parts

Model | Material | ||||||

Body | Seat | Disc | Pull rod | Stem | Gastener | Filler | |

T40H-40 | Carbon steel | Chrome Stainless Steel | Chrome Stainless Steel | Chrome Stainless Steel | Chrome Stainless Steel | steel | Flexible graphite |

T40H-100 | |||||||

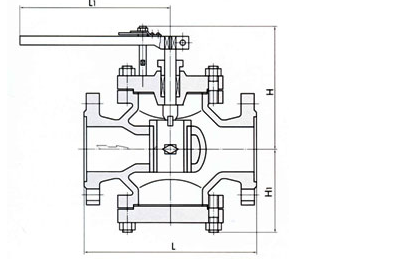

Main External Connection Dimensions

PN | Size(mm) | |||||||||||||

(MPa) | DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 160 | 180 | 200 | 220 | 250 | 280 | 310 | 350 | 400 | 450 | 500 | 650 | 800 |

L1 | 140 | 150 | 180 | 200 | 230 | 240 | 270 | 300 | 350 | 380 | 440 | 500 | 650 | |

H | 180 | 200 | 205 | 210 | 230 | 230 | 250 | 250 | 290 | 300 | 325 | 330 | 450 | |

H1 | 90 | 100 | 107 | 113 | 120 | 125 | 140 | 150 | 190 | 205 | 270 | 270 | 330 | |

2.5 | L | 160 | 180 | 200 | 220 | 250 | 280 | 310 | 350 | 400 | 450 | 500 | 650 | 800 |

L1 | 150 | 160 | 180 | 210 | 245 | 260 | 290 | 320 | 370 | 410 | 480 | 540 | 700 | |

H | 180 | 200 | 205 | 210 | 230 | 240 | 250 | 280 | 290 | 300 | 325 | 330 | 450 | |

H1 | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 | 190 | 205 | 270 | 270 | 335 | |

4.0 | L | 180 | 200 | 220 | 240 | 270 | 300 | 330 | 380 | 450 | 500 | 550 | 650 | 800 |

L1 | 150 | 160 | 190 | 210 | 245 | 270 | 300 | 330 | 380 | 420 | 500 | 560 | 720 | |

H | 180 | 200 | 205 | 210 | 230 | 240 | 250 | 290 | 300 | 310 | 335 | 350 | 470 | |

H1 | 90 | 100 | 110 | 113 | 120 | 130 | 150 | 170 | 190 | 210 | 220 | 290 | 360 | |

6.4 | L | 180 | 200 | 220 | 240 | 270 | 300 | 330 | 380 | 450 | 500 | 550 | 650 | 800 |

L1 | 160 | 170 | 200 | 230 | 260 | 290 | 320 | 350 | 400 | 440 | 530 | 600 | 760 | |

H | 185 | 210 | 220 | 225 | 250 | 250 | 260 | 300 | 310 | 320 | 340 | 360 | 480 | |

H1 | 100 | 110 | 110 | 135 | 35 | 140 | 160 | 180 | 200 | 220 | 230 | 300 | 370 | |