Slag gate valve

Technical Parameter

Item model number: PZ41H

Nominal diameter: DN50~500mm

Nominal pressure: PN1.6~6.4MPa

Working temperature: 0~100℃

Applicable medium: grey water mixture

Main material: WCB, WCB+ wear-resistant alloy

Design and manufacture: GB/T12234, GB/T2595

Flange standard: GB/T9113, JB/T79

Product Description

The wear-resistant slag discharge valve is mainly used in the pipeline of the water conservancy system of the thermal power station and the mortar discharge system of the water conservancy project to cut off or connect the grey water mixture and the slag water mixture in the pipeline. It can also be used for opening and closing of various kinds of abrasive dry dust, water, steam and other media in mining, papermaking, chemical industry, etc. on pipelines.

Features

1. The middle flange bolt connection is adopted, and the two ends of the branch pipe are flange connection or butt welding connection.

2. The opening and closing parts are forcedly sealed by semi-sealing pair, with excellent performance.

3. The material of the sealing pair is wear-resistant ceramic or wear-resistant alloy, which has strong wear resistance, strong wear resistance, durable erosion, scratch resistance, low friction, and reliable sealing.

4. The outlet flow passage of the valve body has a reasonable structure, no slag, flexible opening and closing, and no jamming.

5. The valve stem is quenched and tempered and surface nitrided, which has good corrosion resistance, scratch resistance and wear resistance.

6. The medium and large diameters are equipped with rolling bearings, which can be easily opened and closed.

Main performance specifications

| Model | Nominal pressure | Test pressure | Proper temperature | Applicable media | |

| Strength test | Seal test | ||||

| 1.6 | 2.4 | 1.8 | 22.0 | ≤100℃ | Grey water mixture, slag water ratio 1:6 Maximum particle size<50mm |

| 2.5 | 3.8 | 2.8 | 27.5 | ||

| 4.0 | 6.0 | 4.4 | 35.2 | ||

| 6.4 | 9.6 | 7.1 | 22.0 | ||

Material of main parts

Body | WCB | |

Bonnet | WCB | |

Bracket | WCB | |

Gate | WCB+Wear-resistant alloy | WCB+ceramics |

Stem | 2Cr13 | |

Seat | WCB+Wear-resistant alloy | WCB+ceramics |

Seal ring | Reinforced flexible graphite | |

Packing | Reinforced flexible graphite | |

Stem Nut | ZCuA110Fe3 | |

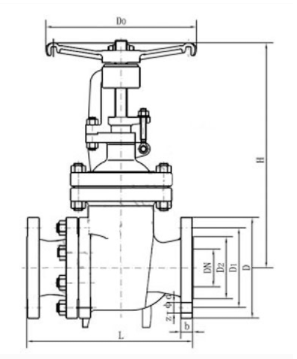

Main external connection dimensions(PN16/25)

| DN | L | D | D1 | D2 | b | z×d | f | H | H1 |

| 50 | 250 | 165 | 102 | 99 | 20 | 4×18 | 3 | 420 | 335 |

| 80 | 280 | 200 | 133 | 132 | 22 | 8×18 | 3 | 615 | 510 |

| 100 | 300 | 220 | 180 | 158 | 24 | 8×18 | 3 | 805 | 685 |

| 150 | 350 | 285 | 240 | 212 | 28 | 8×22 | 3 | 952 | 790 |

| 200 | 400 | 340 | 295 | 268 | 30 | 12×22 | 3 | 1085 | 885 |

| 250 | 450 | 405 | 355 | 320 | 32 | 12×26 | 3 | 1235 | 1015 |

| 300 | 500 | 460 | 410 | 370 | 34 | 12×26 | 4 | 1450 | 1190 |

| 350 | 550 | 520 | 470 | 430 | 38 | 16×26 | 4 | 1640 | 1350 |

| 400 | 600 | 580 | 525 | 482 | 40 | 16×30 | 4 | 1798 | 1460 |

| 450 | 650 | 640 | 585 | 532 | 44 | 21×30 | 4 | 1980 | 1620 |

| 500 | 700 | 715 | 650 | 585 | 46 | 20×33 | 4 | 2190 | 1800 |

Main external connection dimensions(PN40)

| DN | L | D | D1 | D2 | b | z×d | f | H | H1 |

| 50 | 250 | 165 | 125 | 88 | 20 | 4×18 | 3 | 444 | 340 |

| 80 | 310 | 200 | 160 | 121 | 22 | 8×18 | 3 | 636 | 508 |

| 100 | 350 | 235 | 190 | 150 | 24 | 8×22 | 3.5 | 930 | 680 |

| 150 | 450 | 300 | 250 | 204 | 30 | 8×26 | 3.5 | 984 | 800 |

| 200 | 550 | 375 | 320 | 260 | 38 | 12×30 | 3.5 | 1094 | 875 |

| 250 | 650 | 450 | 382 | 313 | 42 | 12×33 | 3.5 | 1270 | 1010 |

| 300 | 750 | 515 | 450 | 364 | 46 | 16×33 | 3.5 | 1470 | 1180 |

| 350 | 850 | 580 | 510 | 422 | 52 | 16×36 | 4 | 1555 | 1245 |

| 400 | 950 | 660 | 585 | 474 | 58 | 16×39 | 4 | 1650 | 1280 |

| 450 | 4050 | 685 | 610 | 524 | 60 | 20×39 | 4 | 1817 | 1415 |

| 500 | 1150 | 755 | 670 | 576 | 62 | 20×42 | 4 | 1990 | 1560 |

Main external connection dimensions(PN64)

| N | L | D | D1 | D2 | b | z×d | f | H | H1 |

| 50 | 250 | 180 | 135 | 88 | 26 | 4×22 | 3 | 444 | 340 |

| 80 | 310 | 215 | 170 | 121 | 30 | 8×22 | 3 | 636 | 508 |

| 100 | 350 | 250 | 200 | 150 | 32 | 8×26 | 3.5 | 830 | 680 |

| 150 | 450 | 345 | 280 | 204 | 38 | 8×33 | 3.5 | 984 | 800 |

| 200 | 550 | 415 | 345 | 260 | 44 | 12×36 | 3.5 | 1094 | 875 |

| 250 | 650 | 470 | 400 | 212 | 48 | 12×36 | 3.5 | 1270 | 1010 |

| 300 | 750 | 530 | 460 | 364 | 54 | 16×36 | 3.5 | 1470 | 1180 |

| 350 | 850 | 600 | 525 | 422 | 60 | 16×39 | 4 | 1555 | - |

| 400 | 950 | 670 | 585 | 474 | 66 | 16×42 | 4 | 1650 | 1280 |

| 450 | 1050 | 715 | 630 | 524 | 70 | 20×42 | 4 | 1817 | 1415 |

| 500 | 1150 | 800 | 705 | 476 | 76 | 20×48 | 4 | 1990 | 1560 |