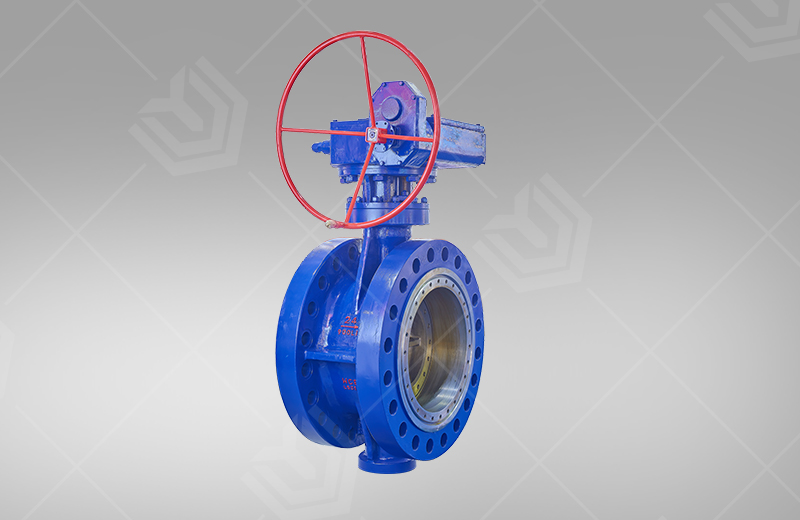

Electric high temperature and high pressure welding globe valve

Technical Parameter

Product model: J961H/Y

Nominal diameter: DN20~100mm

Nominal pressure: PN10.0-32.0MPa, P54/100V-170V

Main material: cast steel, stainless steel, forged steel, chrome molybdenum steel, chrome molybdenum vanadium steel

Drive mode: electric

Product Description

Electric high temperature and high pressure welding globe valve can adopt special structure and corresponding seal according to different pressure and temperature. The pressure test is 1.5 times of the working pressure to ensure that the valve will not leak under the working pressure. At the same time, it is ensured that under the corresponding temperature, the seal will not be deformed, and the phenomenon of loose sealing will not occur. This valve is one of the most widely used valves in electric power, electrical, electromechanical equipment engineering, and electronic control equipment engineering. Because of its convenient installation, reasonable manufacturing and economic simplicity, it is widely used in pipelines such as power engineering.

Product Features

1. The connection between the valve and the pipeline adopts a welded structure.

2. The machining of the valve body and the valve cover is all completed on the automatic line, which has the characteristics of light weight and high machining accuracy.

3. The valve seat and valve disc sealing surface are all made of cobalt-based cemented carbide plasma spray welding, which has good wear resistance and scratch resistance.

4. The surface of the valve stem is treated with anti-corrosion nitriding.

5. It is suitable for water, steam and oil pipelines, and has the characteristics of high temperature resistance and high pressure resistance.

Main performance specifications

| Product number | PN/MPa | Test pressure/MPa | Work pressure/MPa | Operating temperature(℃) | Applicable media | |||

| Shell strength | Seal | P45 | P55 | P57 | ||||

| J961H Y-100 | 10 | 15 | 11 | / | / | / | ≤450 | Water, steam, oil |

| J961H Y-200 | 20 | 30 | 22 | / | / | / | ||

| J961H Y-250 | 25 | 38 | 28 | / | / | / | ||

| J961H Y-320 | 32 | 48 | 36 | / | / | / | ||

| J961Y-P54/100V | / | 30 | 22 | 10 | / | / | ≤540 | Steam |

| J961Y-P54/140V | / | 38 | 28 | 14 | / | / | ||

| J961Y-P54/170V | / | 48 | 36 | 17 | / | / | ||

| J961Y-P55/100V | / | 38 | 28 | / | 10 | / | ≤555 | |

| J961Y-P55/140V | / | 48 | 36 | / | 14 | / | ||

| J961Y-P55/170V | / | 53 | 39 | / | 17 | / | ||

| J961Y-P57/100V | / | 48 | 36 | / | / | 10 | ≤570 | |

| J961Y-P57/140V | / | 55 | 40 | / | / | 14 | ||

| J961Y-P57/170V | / | 60 | 44 | / | / | 17 | ||

Material properties

| Part Name | Valve | Cap | Stem | Disc | Sealing surface | filler | Stem Nut | Fastener |

| J961H | 25 WCB | 25 40Cr | Chrome stainless steel, chromium molybdenum aluminum steel ammoniated | Chrome Stainless Steel | Chrome Stainless Steel | Flexible graphite | aluminum bronze | High quality carbon steel, chrome molybdenum steel |

| J961Y | 25 WCB | 25 40Cr | Chrome stainless steel, chromium molybdenum aluminum steel ammoniated | 25 | Carbide | High quality carbon steel, chrome molybdenum steel | ||

| J961Y-P54 | ZG20CrMoV 12Cr1Mo1V | 12Cr1Mo1V | 20Cr1Mo1VA 25Cr2Mo1VA | 12Cr1Mo1V | Carbide | Chrome-molybdenum steel | ||

| J961Y-P55 | ZG15CrMoV 12Cr1Mo1V | 12Cr1Mo1V | 20Cr1Mo1VA 25Cr2Mo1VA | 12Cr1Mo1V | Carbide | Chrome-molybdenum steel | ||

| J961Y-P57 | ZG15CrMoV 12Cr1Mo1V | 12Cr1Mo1V | 20Cr1Mo1VA 25Cr2Mo1VA | 12Cr1Mo1V | Carbide | Chrome-molybdenum steel |

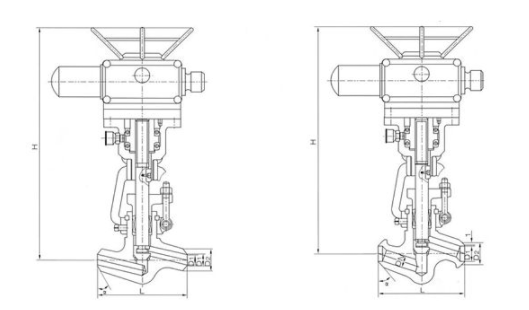

Main external connection dimensions

Model | DN | d | L | L1 | L2 | H | Denso model |

J961Y-250 | 20 | 19 | 150 | 363 | 197 | 576 | DZW15 |

25 | 22 | 180 | 363 | 197 | 590 | DZW15 | |

32 | 26 | 180 | 363 | 197 | 606 | DZW15 | |

40 | 36 | 250 | 363 | 197 | 722 | DZW20 | |

50 | 42 | 250 | 363 | 197 | 722 | DZW30 | |

65 | 56 | 340 | 473 | 277 | 1060 | DZW45 | |

80 | 80 | 390 | 526 | 283 | 1280 | DZW90 | |

100 | 84 | 480 | 526 | 283 | 1290 | DZW90 | |

J961Y-320 | 20 | 19 | 150 | 363 | 197 | 276 | DZW15 |

25 | 22 | 180 | 363 | 197 | 590 | DZW15 | |

32 | 26 | 180 | 363 | 197 | 606 | DZW15 | |

40 | 36 | 250 | 363 | 197 | 722 | DZW20 | |

50 | 42 | 250 | 363 | 197 | 722 | DZW30 | |

65 | 60 | 470 | 526 | 283 | 1140 | DZW90 | |

80 | 80 | 570 | 526 | 283 | 1350 | DZW120 | |

100 | 96 | 660 | 554 | 609 | 1500 | DZW180 | |

J961Y-P57170V | 20 | 19 | 150 | 363 | 197 | 576 | DZW15 |

25 | 22 | 180 | 363 | 197 | 590 | DZW15 | |

32 | 26 | 180 | 363 | 197 | 606 | DZWl5 | |

40 | 36 | 250 | 363 | 197 | 722 | DZW20 | |

50 | 42 | 250 | 363 | 197 | 722 | DZW30 | |

65 | 60 | 762 | 526 | 283 | 1543 | DZW90 | |

80 | 74 | 864 | 526 | 283 | 1790 | DZWl20 | |

100 | 88 | 965 | 554 | 309 | 1890 | DZWl80 |